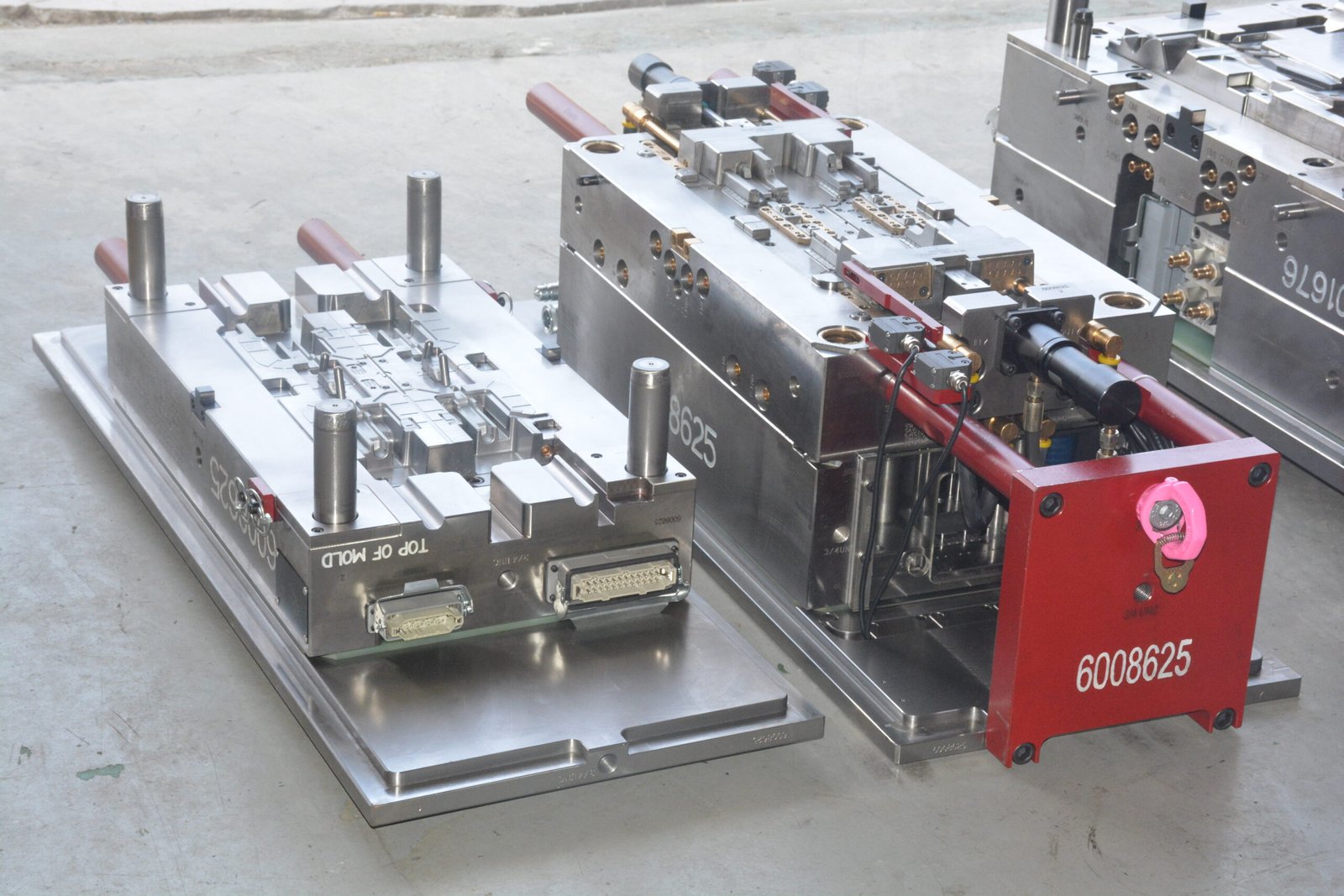

Complex Mold Manufacturing

Precision Injection Mold Solutions

Elevate Quality

Shorten Production Cycles

- Rapid Delivery in 4 Weeks

- 20 Years of Industry Experience

- High-Precision Manufacturing to ±0.01mm

At GBM Mold Technology, we're committed to delivering exceptional value through our precision injection mold solutions. With over two decades of industry expertise and more than 2,000 successful projects, we've established ourselves as a trusted partner for businesses seeking high-quality, efficient manufacturing solutions.

Happy Wong Tweet

GBM was founded in 2012, GBM Mold Technology Co., Ltd is a National High-Tech Enterprise specializing in precision molds and one-stop injection molding services. .We provide one-stop injection molding services, coveringproduct design, mold design, manufacturing, andproduction.

- Over 10 experienced project engineers and 20 project managersfluent in English

- At least 9 stringent checks for each mold.Achieving machining accuracy of up to 0.005 mm.

- In-house injection molding workshop, clean room, andhigh-speed injection molding machines

- With an average lead time of just 1 to 4 weeks from T1 to shipping approval

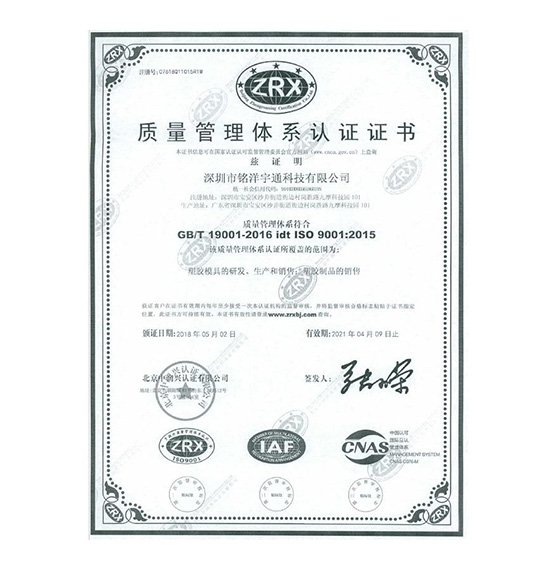

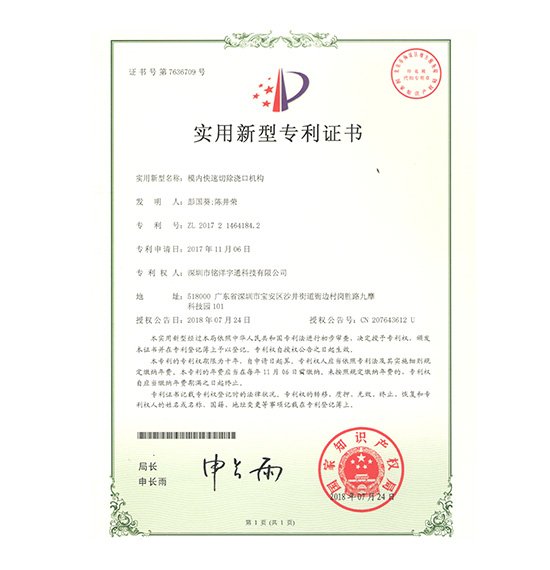

- We have many certificates: TUV, ISO9001, TS16949, ISO14001.

Our Expertise

We specialize in four key areas of mold technology

Insert Molding

Quantity of inserts: more than 1,400. Designer: Andy Gao

2 Shot Molds

1st shot PA/ABS+ 2nd shot TPV 4 lifers driven by hydraulic cylinder

Unscrewing Mold

Quantity of inserts: more than 1,400. Designer: Andy Gao

Connector Molds

Quantity of inserts: more than 1,400. Designer: Andy Gao

GBM's Core Services

Save Worry, Save Trouble, Save Cost

Design & Engineering

we offer cutting-edge solutions for complex mold structures across automotive, medical, and electronic industries.

Manufacturing

Our expertise spans over two decades, ensuring precision and quality in every project.complex mold manufacturing.

Quality Assurance

We implement rigorous quality control measures for both injection mold manufacturing and injection molding processes

After Sales Support

We offer robust after-sales support to ensure the longevity and optimal performance of our molds and molded products.

- Advanced CAD/CAM design for complex mold structures

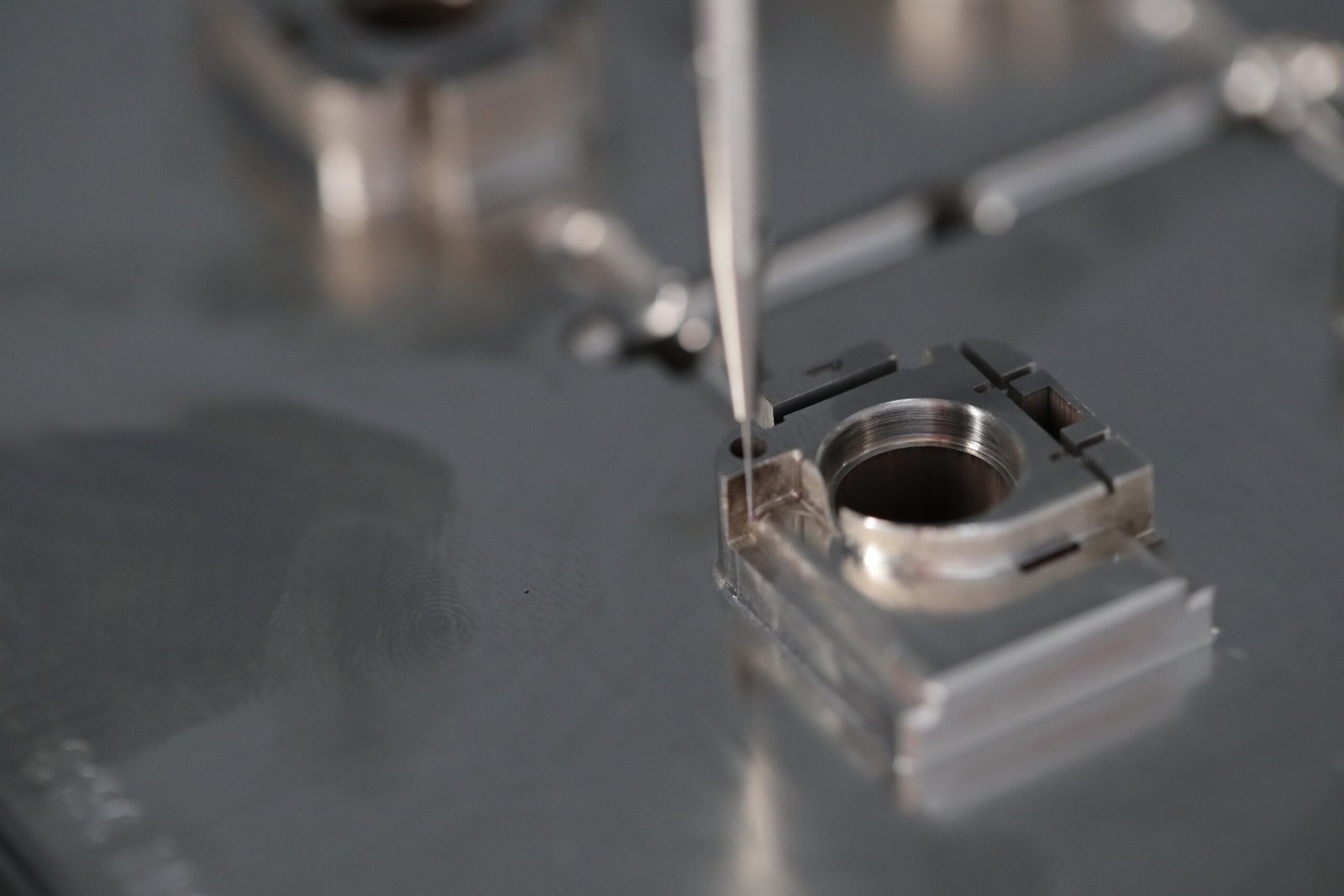

- High-precision CNC and EDM machining

- Specialized insert positioning systems

- Rapid prototyping and production capabilities

- High-speed production with state-of-the-art equipment

- Multi-material and multi-color molding

- Precision parts manufacturing

- Comprehensive in-process quality control

- Mold flow analysis and optimization

- Mold modification and repair

- Regular maintenance to ensure mold longevity

- Insert molding for metal-plastic integration

- 2-shot molding for multi-material components

- Unscrewing molds for threaded parts

- Connector molds for electrical components

- Rigorous quality control at every production stage

- Advanced CMM and vision system inspections

- Material testing and analysis

- Expert technical consultation

- Project management from design to delivery

- Training and support for mold operation

- Advanced CAD/CAM design for complex mold structures

- High-precision CNC and EDM machining

- Specialized insert positioning systems

- Rapid prototyping and production capabilities

- High-speed production with state-of-the-art equipment

- Multi-material and multi-color molding

- Precision parts manufacturing

- Comprehensive in-process quality control

- Mold flow analysis and optimization

- Mold modification and repair

- Regular maintenance to ensure mold longevity

- Insert molding for metal-plastic integration

- 2-shot molding for multi-material components

- Unscrewing molds for threaded parts

- Connector molds for electrical components

- Rigorous quality control at every production stage

- Advanced CMM and vision system inspections

- Material testing and analysis

- Expert technical consultation

- Project management from design to delivery

- Training and support for mold operation

Industries We Serve

Our expertise and advanced technologies allow us to meet the diverse needs of various sectors.

Automotive

Structural components like dashboards and bumpers

Medical Devices

High-precision, high-cleanliness molds

Electronics

Quantity of inserts: more than 1,400. Designer: Andy Gao

Aerospace

Lightweight, high-strength parts for aircraft interiors and systems

At GBM Mold Technology, our commitment to quality is ingrained in every step of our process.

1、Design Phase QC

- Utilize advanced CAD software

- Conduct mold flow analysis

- Hold design review meetings

2、Material Inspection

- Perform spectral analysis on each batch mold steel

- Conduct hardness tests on steel materials

- Dimensional inspection

3、Machining QC

- Implement "inspection at every process" principle

- Use CNC machining centers up to ±0.01mm

- Conduct 100% dimensional inspection

4、Assembly/Testing QC

- Re-check precision before assembly

- Inspect mold opening/closing clearance and parallelism

- Test cooling system sealing and ejector system smoothness

5、Final Inspection

- Use coordinate measuring machines (CMM)

- Conduct mold life testing

At GBM Mold Technology, we implement a rigorous quality control process throughout the mold manufacturing lifecycle to ensure the highest standards of precision and reliability.

1、Material Preparation QC

- Strict selection of high-quality raw materials

- Precise control of material drying process

- Material blending according to product requirements

2、Production Process Control

- Real-time monitoring of injection parameters

- Regular inspections to promptly identify and resolve issues

- Strict control of production environment, especially clean room management

3、Product Quality Inspection

- Comprehensive inspection of first article samples

- Regular sampling inspection during production

- 100% final inspection before shipment

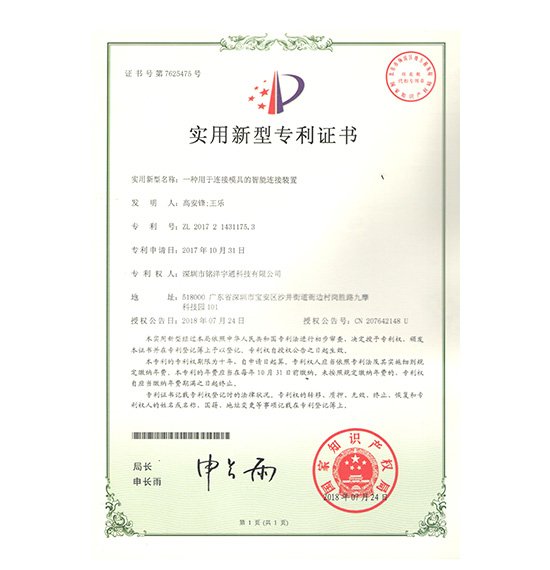

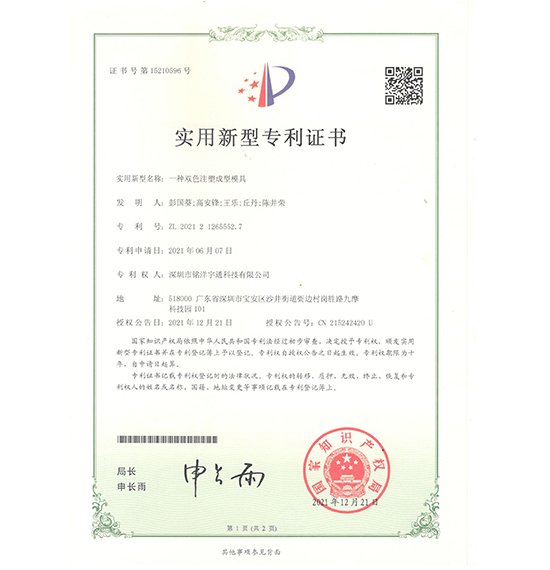

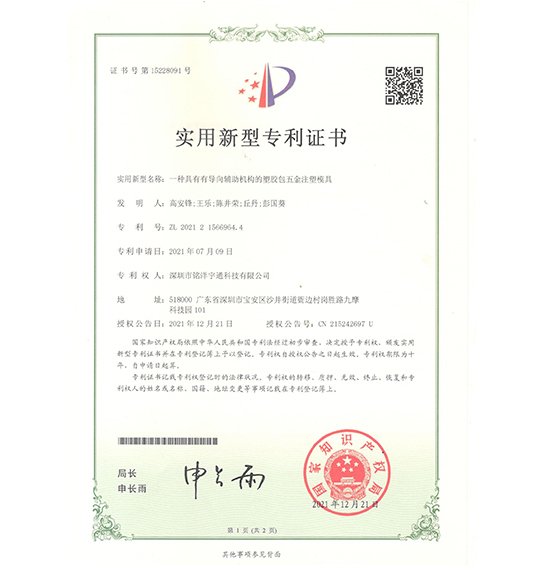

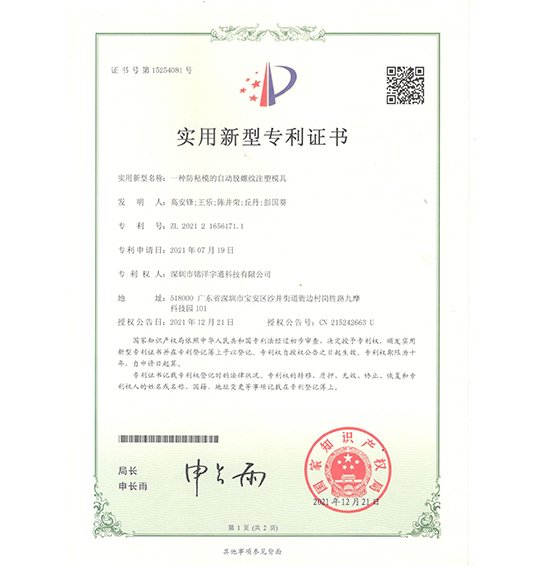

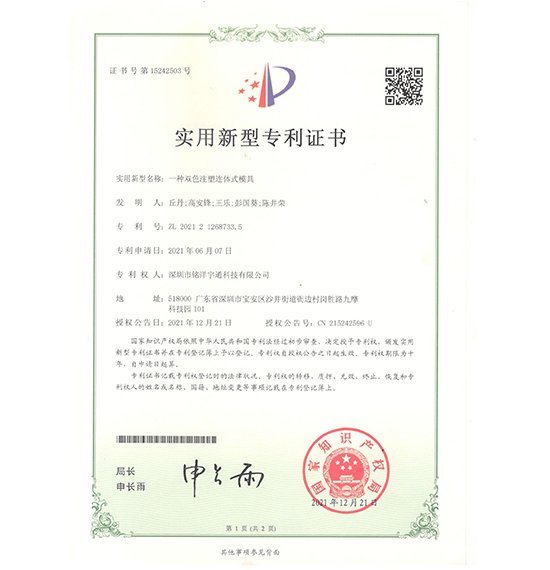

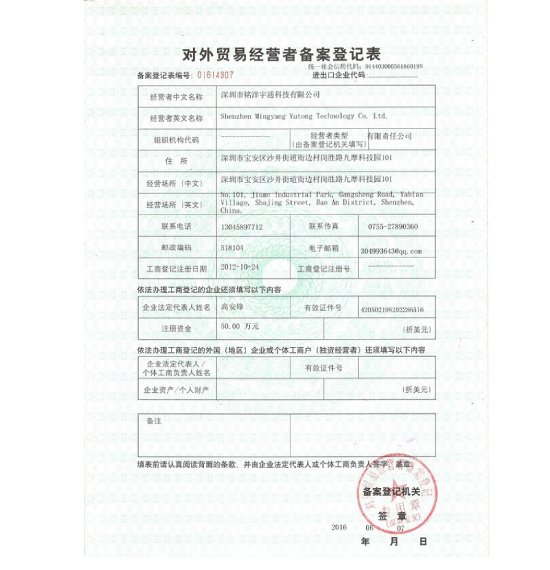

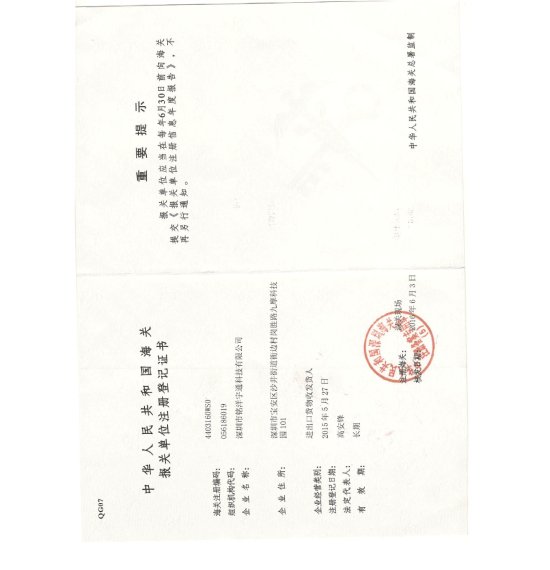

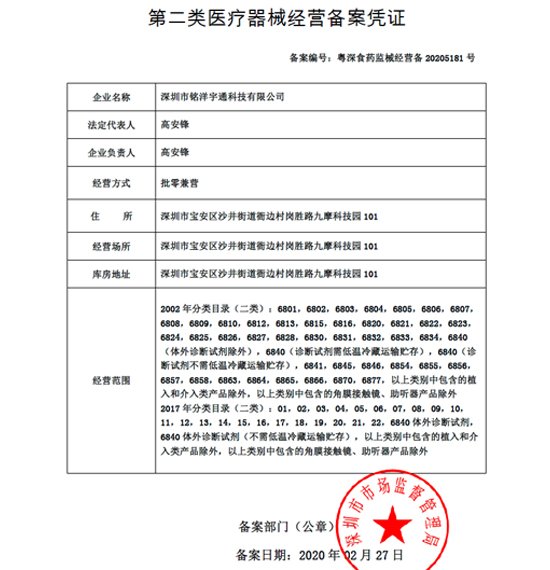

GBM Certification

GBM Mould Blogs

Custom Plastic Enclosure Plastic Injection Parts by Injection Molding with Design Structure Optimization

Let's Talk

- Factory Address: 101, Building 1, Jiumo Tech, Shajing, Bao'an District, SZ, CN

- +86-0755-27691164

- +86 13632611848

- info@gbmmould.com

If you have a great idea, we can help bring it to life. We’ve done this before and enjoy becoming partners throughout product creation. From advising you through the mold sourcing process to delivering your new product to customers, we want to work with you every step of the way.